PT Green Energy Geothermal

OUR SERVICES

Need Our Service?

Looking to optimise performance or streamline operations?

We’re here to help you find the right solution.

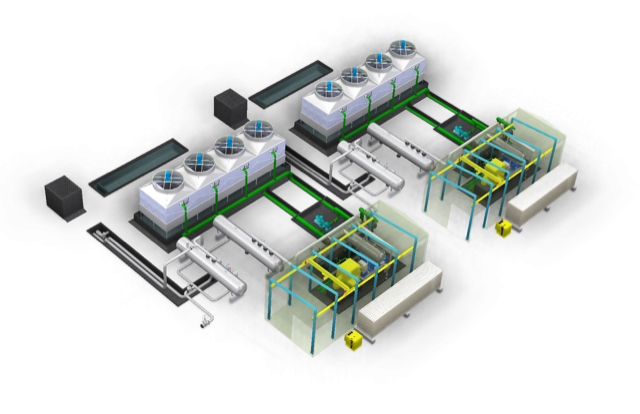

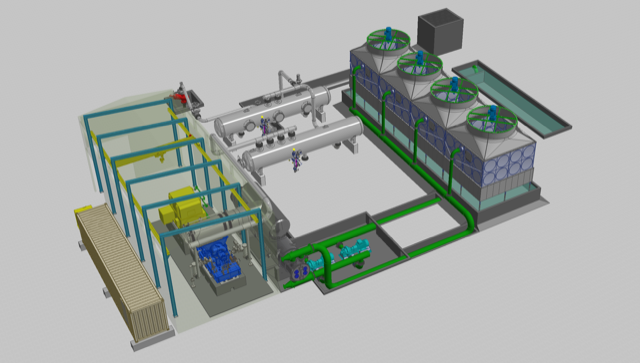

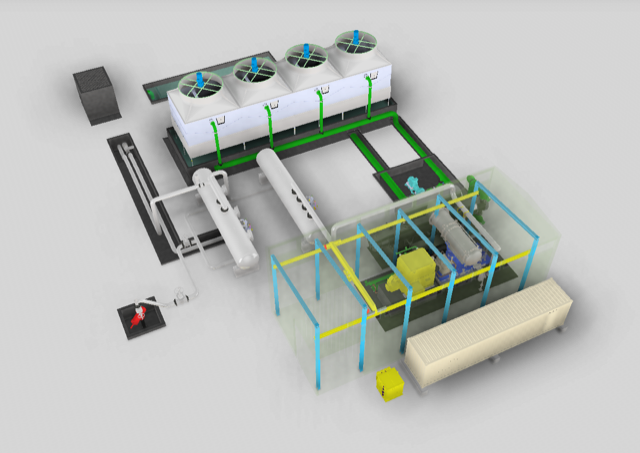

POWER PRODUCTION

In the power production category, GEGI presents three state-of-the-art modular geothermal power plants, each accompanied by their respective subsystems:

- NG120 (12 MW)

- NG60 (6.0 MW)

- NG75bp (7.5 MW)

The NG75 can be supplied with a dedicated 7.5 MW back pressure turbine, or a 6.7 MW modified 12 MW unit from an NG120 plant that can be converted back to a condensing unit at a later date.

- Direct Contact Condenser

- Surface Condenser

- Ejector Type Vacuum System

- Liquid Ring Vacuum Pump

- Direct Contact Condenser

- Surface Condenser

- Ejector Type Vacuum System

- Liquid Ring Vacuum Pump

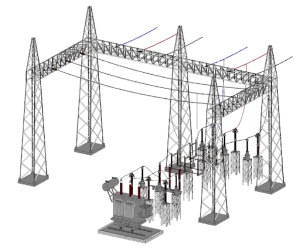

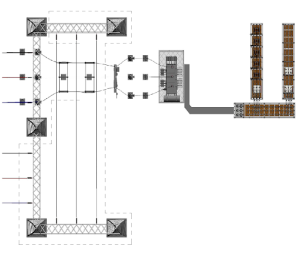

POWER DISTRIBUTION

The company has developed two modular step-up-stations, the SA8 and the SA37.

The SA37 step-up station is specifically designed to facilitate the voltage step-up process for multiple well-head power plants. This modular station offers scalability and modularity, ranging from 15 to 120 MW and up to a dispatch voltage of 240 kV. It is constructed with two transformer setups, with the option to populate either one or both. The SA37 step-up station can efficiently service up to:

- 8 NG120 Well-head Power Plants

- 16 NG60 Well-Head Power Plants

Providing reliable power transmission capabilities. The design of the SA37 step-up station encompasses all essential elements, including civil works, mechanical components, and electrical designs. Moreover, the control system of the station incorporates certain ancillary and auxiliary system designs shared with the control system design of the power plants. This integration ensures a cohesive and synchronized operation between the step-up station and the connected well-head power plants, enhancing overall system efficiency and performance.

The SA8 mobile 3.2 step-up-station is designed for temporary and/or permanent applications in the output range of 8-16 MVA @ 20-60 kV. Its primary design goal was to step-up the company’s wellhead plants 11 kV supply voltage to a medium voltage local network of up to 70 kV. It can be configured to service a:

- Single NG120 wellhead power plant

- Single NG75bp wellhead power plant

- Single NG60 wellhead power plant

- Two NG60 wellhead power plant

The step-up-station is mounted on a 40’ ISO container skid for mobility and ease of mounting where it is to be used. It is designed as a self-containing unit with all its features build in to and on to the skid, such as oil trap, breakers, and controls. As the design is relatively flexible, it can be configured for different input voltage to be used as an emergency step-up-station for multiple generators during disaster relief or as emergency power hub.

PROCESS APPLICATION

Considerable effort has been put into generating computational models or applications with defined user inputs for determining power plant output under different environmental and load conditions for different plant setups. The model plant setups are a:

- Single flash steam cycle

- Double flash steam cycle

- ORC cycle

- Back pressure cycle

- A mix of all

- Ejector vacuum system

- Liquid ring vacuum pump

- Direct contact condenser

- Surface condenser

The models are constructed with the characteristics of the components from our preapproved vendors build in. These models make it simpler and easier to analyse different operating scenarios for or plant designs under.